Pressurized Furnaces designed by GMS are divided into Medium Frequency Coreless Furnaces (especially for Ductile Iron casting), also called “Coreless-type Autopour”, and Channel Furnaces (for Grey Cast Iron), also called “Channel-type Autopour“.

Furnaces for Automatic Casting

GMS produces Induction Casting and/or Holding Furnaces for the Automatic Casting of Grey Cast Iron, Ductile Iron, Copper and Copper Alloys in various formats.

“Autopour” Pressure Furnace

“Autopour” Pressure Furnace

Automatic Pouring Furnace “Pour Mate®”, 100 kg crucible capacity – 150 kW electrical power

Automatic Pouring Furnace “Pour Mate®”

Automatic Pouring Furnace “Pour Mate®” – control chamber for molding lines filling

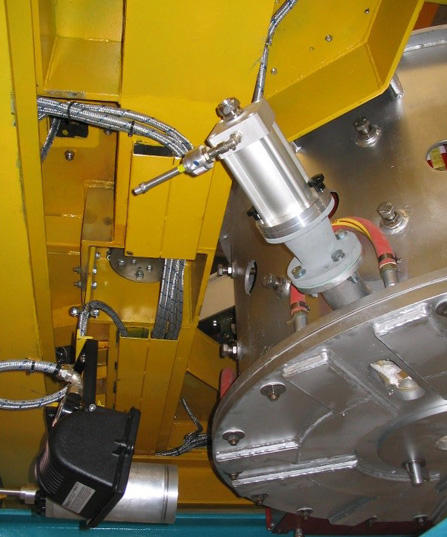

GMS Pour Mate® Furnace is an Induction Coreless-type Furnace positioned directly above the molding line, designed for the Automatic Casting of Cast Iron from the bottom through Stopper and Graphite Nozzle, electrically operated and equipped with automatic positioning in axis with the sprue cup and with an automatic system of molding lines filling control.

Electric Power and Control Panel is powered by an IGBT Converter, the Furnace connection cables are cooled. The Automatic Inoculation System in the pipeline casting flow passes through the Furnace structure. The supporting structure of the Furnace is to be considered adaptable both to vertical fast-moving forming lines (for example, “Disamatic®”) and to horizontal fast-moving forming lines with mold lines of various sizes.

The Pour Mate® Furnace is truly innovative, reliable and easy to maintain thanks to the features as rapid interchangeability of the crucible-inductor unit; its structure, dimensions and positioning of the Furnace on load cells; automatic compressed air cleaning system.

These most important peculiarities of Pour Mate® enable to cast without uncertainties or unexpected stops, with a substantial increase in industrial productivity and quality of the casting products.

Italiano

Italiano

Latest News